The Battery 2025-2032 Conundrum: A Tale of Two Decades, One Critical Resource

The year is 2025. The world is grappling with the consequences of climate change, with a growing urgency to transition away from fossil fuels. Electric vehicles are becoming increasingly popular, and the demand for batteries is skyrocketing. The race to secure critical minerals for battery production is on, and the question of whether the world can meet the demand by 2032 is a pressing one.

This is the reality of the "Battery 2025-2032 Conundrum," a complex interplay of factors that will determine the success or failure of the global energy transition. While 2025 marks a crucial juncture in the timeline, the year 2032 represents a critical target for achieving ambitious climate goals. By that year, many countries aim to have significantly reduced their reliance on fossil fuels, with electric vehicles playing a central role.

This article delves into the intricacies of this conundrum, exploring the challenges and opportunities surrounding battery production and the critical minerals needed to power the transition. We will examine the current state of the battery market, the global demand projections, and the potential bottlenecks in the supply chain. We will also analyze the geopolitical implications of this race for resources, the role of technology in mitigating the challenges, and the need for a collaborative approach to ensure a sustainable future.

The Battery Boom: A Technological Catalyst for Change

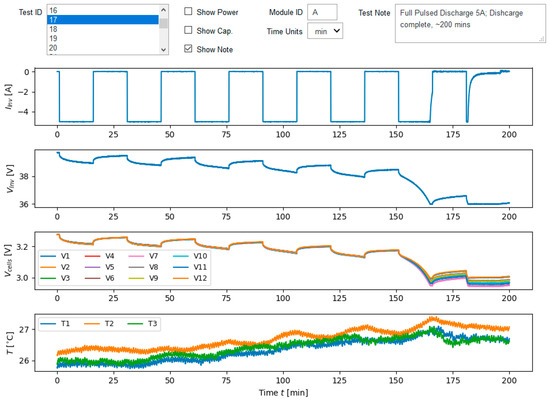

Lithium-ion batteries, the dominant technology in the electric vehicle market, are at the heart of the energy transition. Their ability to store energy efficiently and deliver high power output has revolutionized transportation and energy storage solutions. This surge in demand has fueled an unprecedented boom in the battery industry, attracting investment and innovation from major players across the globe.

However, the rapid growth of the battery market comes with significant challenges. The production of lithium-ion batteries requires a diverse range of critical minerals, including lithium, cobalt, nickel, manganese, and graphite. The supply of these minerals is geographically concentrated, with a few countries dominating the global market. This dependence on a limited number of suppliers raises concerns about price volatility, supply chain disruptions, and potential geopolitical tensions.

The Global Demand: A Race Against Time

The International Energy Agency (IEA) estimates that by 2030, the global demand for lithium-ion batteries will increase tenfold compared to 2020. This surge is driven by the growing adoption of electric vehicles, the increasing deployment of renewable energy sources like solar and wind, and the development of energy storage solutions for grid stability.

The demand for critical minerals is expected to follow suit. The IEA predicts that the demand for lithium will increase by 42 times, cobalt by 25 times, and nickel by 19 times by 2040. This exponential growth in demand creates a significant challenge for the global supply chain, raising concerns about whether the world can produce enough critical minerals to meet the projected demand.

The Supply Chain Bottlenecks: A Complex Puzzle

The production of critical minerals is a complex and resource-intensive process, often involving environmentally sensitive mining practices and significant transportation distances. This complexity creates a number of potential bottlenecks in the supply chain, which could hinder the global transition to a low-carbon future.

1. Mining Capacity and Environmental Concerns:

Expanding mining operations to meet the growing demand for critical minerals presents a significant challenge. Mining operations often involve land use changes, potential environmental impacts, and social conflicts with local communities. Balancing the need for critical minerals with environmental sustainability is crucial.

2. Processing and Refining Capabilities:

The processing and refining of critical minerals require specialized infrastructure and expertise. The current capacity of processing facilities may not be sufficient to handle the projected surge in demand, potentially leading to delays and disruptions in the supply chain.

3. Transportation and Logistics:

The transportation of critical minerals from mines to processing facilities and then to battery manufacturers involves significant distances and complex logistics. This presents challenges in terms of efficiency, cost, and environmental impact, particularly for countries with limited infrastructure.

4. Recycling and Circular Economy:

Recycling critical minerals from end-of-life batteries is crucial for reducing dependence on primary mining and mitigating environmental impacts. However, current recycling rates are low, and the development of efficient and cost-effective recycling technologies is essential.

The Geopolitical Implications: A Shifting Landscape

The global race for critical minerals has significant geopolitical implications. Countries with abundant reserves of critical minerals are strategically positioned to influence the global energy transition. This has led to increased competition for resources, potential trade disputes, and the formation of strategic alliances.

1. Resource Nationalism:

Several countries with significant reserves of critical minerals have implemented policies to restrict exports or prioritize domestic use. This "resource nationalism" can create supply chain disruptions and impact the global availability of these critical materials.

2. Strategic Partnerships:

Countries are forming strategic partnerships to secure access to critical minerals and ensure a stable supply chain. These partnerships can involve joint ventures, investment agreements, and technology sharing.

3. Global Governance and Cooperation:

The need for global governance and cooperation is paramount to ensure the responsible and sustainable production and distribution of critical minerals. International agreements and collaborative initiatives are essential to address challenges related to environmental protection, social equity, and geopolitical stability.

Technological Solutions: A Path to Resilience

Technological innovation plays a crucial role in mitigating the challenges associated with the Battery 2025-2032 Conundrum. Advances in battery technology, mining techniques, and recycling processes can help address the issues of resource scarcity, environmental impact, and supply chain resilience.

1. Battery Technology Advancements:

Researchers are exploring alternative battery chemistries that require fewer critical minerals or utilize more abundant resources. Solid-state batteries, for example, offer potential advantages in terms of energy density, safety, and longevity.

2. Sustainable Mining Practices:

Technological advancements in mining techniques can reduce the environmental footprint of extraction operations. This includes using less water, minimizing land disturbance, and developing more efficient and selective extraction methods.

3. Recycling and Circular Economy Solutions:

Innovations in battery recycling technologies can improve the recovery rates of critical minerals from end-of-life batteries. This includes developing new processes for separating and extracting valuable materials from complex battery mixtures.

A Collaborative Approach: The Key to Success

The Battery 2025-2032 Conundrum requires a collaborative approach involving governments, industry, researchers, and civil society. This collaboration is essential to ensure the responsible and sustainable production and use of critical minerals, while also mitigating potential risks to the environment and society.

1. Policy and Regulation:

Governments need to implement policies that promote responsible mining practices, support the development of recycling technologies, and incentivize the use of sustainable battery technologies.

2. Industry Collaboration:

Industry players need to work together to develop standardized recycling processes, share best practices for sustainable mining, and collaborate on research and development efforts.

3. Public Engagement:

Public awareness and engagement are crucial for building support for the transition to a low-carbon future. This includes educating the public about the importance of critical minerals, the challenges of responsible sourcing, and the role of recycling.

Conclusion: A Road Map for a Sustainable Future

The Battery 2025-2032 Conundrum presents a complex set of challenges and opportunities. By addressing the issues of resource scarcity, environmental impact, and geopolitical tensions, the world can harness the power of batteries to accelerate the transition to a clean energy future. This requires a collaborative approach, technological innovation, and a commitment to sustainable practices. The success of this endeavor hinges on the collective efforts of governments, industry, researchers, and civil society. Only through a united and responsible approach can we ensure a sustainable and prosperous future powered by batteries.